GALILEE FURNITURE

רהיטי גליל

©HOMAG

Galilee Furniture (1970 Export) Ltd. factory was established in Nahariya in 1969 by Mr. Hans Freund and has been managed by his son Dani Freund since 1980.

Galilee Furniture specializes in major custom furniture projects for large institutions and business enterprises all over the country.

Each element of furniture is manufactured according to the client's order and the plans prepared by his architect.

While we have the greatest respect for architectural plans we also send our own teams to take exact measurements on site. We then prepare our own drawings detailing all aspects of the project, thus ensuring an exact fit and perfect coordination with all other systems and trades involved in the project.

For this purpose we maintain a large and experienced planning department whose function is to break up architectural plans into the finest details and cooperate with architects to provide our clients with products that meet their requirements perfectly.

our plant occupies about 3,000 sq.m. of floor space and contains modern computerized equipment for efficient and precise production, and our employees are highly qualified professionals with years of experience in the industry who work together as a team to successfully manufacture and install large and complex furniture systems.

Company Profile

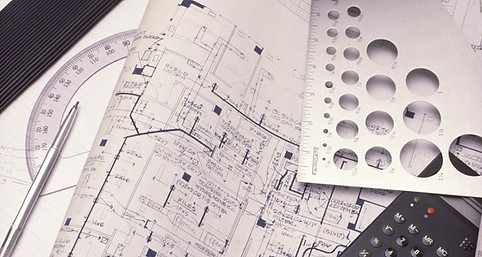

The Planing Department

Each and every project at Galilee Furniture factory starts in the planning department, where highly skilled and experienced planners transform architectural plans into detailed and precise production plans.

Factory planners are in constant communication with project architects and managers, responding swiftly to any request for changes or updates.

Once the architects of our customers approve the proposed projects, detailed implementation plans are transferred to the production department.

The Machinery Section

The first step in the production of the parts of a furniture is processed at this section.

Galilee Furniture uses two up-to-date bridge saws, completely synchronized with the Planning Department. The bridge saws cut the different raw materials into the sizes specified by the project. The different parts are then passed through two modern CNC machines with multi spindles, which execute three dimensional drilling and routing.

This Section is also equipped with advanced edge banding and sanding machines and a variety of saws for different purposes.

Assembly and Coloring Section

The different parts of a furniture are put together in this section. These area is manned by competent and experienced carpenters who verify meticulously project details to ensure quality finish.

Our team of color specialists creates the most suitable final finish for each set of furniture applying high quality colors and varnishes.

Finished products are subsequently transported to their destination and installed by the same people who worked on them.